Japanese Vehicle Delivers New Hardware for NASA’s Robotic Refueling Mission

It may be called the Robotic Refueling Mission (RRM), but NASA’s RRM was built to demonstrate much more than the clever ways space robots can fill up satellites.

With the launch of new hardware to the International Space Station on Aug. 3, RRM – recently named a “Top Exploration Technology Application From the International Space Station in 2012” – will be outfitted to practice a new set of satellite-servicing activities.

New Hardware for a New Era of Satellite-Servicing Demonstrations

Earlier in 2013, RRM demonstrated remotely controlled robots using today’s technology could refuel satellites not designed to be serviced. RRM tests from January 14 to 25 culminated in a first-of-its-kind robotic fluid transfer.

Following the success of completing this namesake task, in 2014 RRM will demonstrate how space robots can replenish cryogen (a type of refrigerant) in the instruments of legacy satellites–existing, orbiting spacecraft not originally designed to be serviced.

“Just like robotic refueling, there were a lot of folks who said that this simply couldn’t be done,” says Benjamin Reed, deputy project manager of the Satellite Servicing Capabilities Office (SSCO) at NASA’s Goddard Space Flight Center in Greenbelt, Md.

“But that’s the whole point of the RRM demonstrations – and the beauty of being able to execute them on such an extraordinary test bed as the space station. RRM is allowing us to show that the robotic satellite-servicing tools, technologies and techniques are mature and ready, because we’ve proven them on orbit.”

Delivery to Space Station and Installation

New hardware deliveries to the space station will outfit the RRM module for this upcoming set of operations.

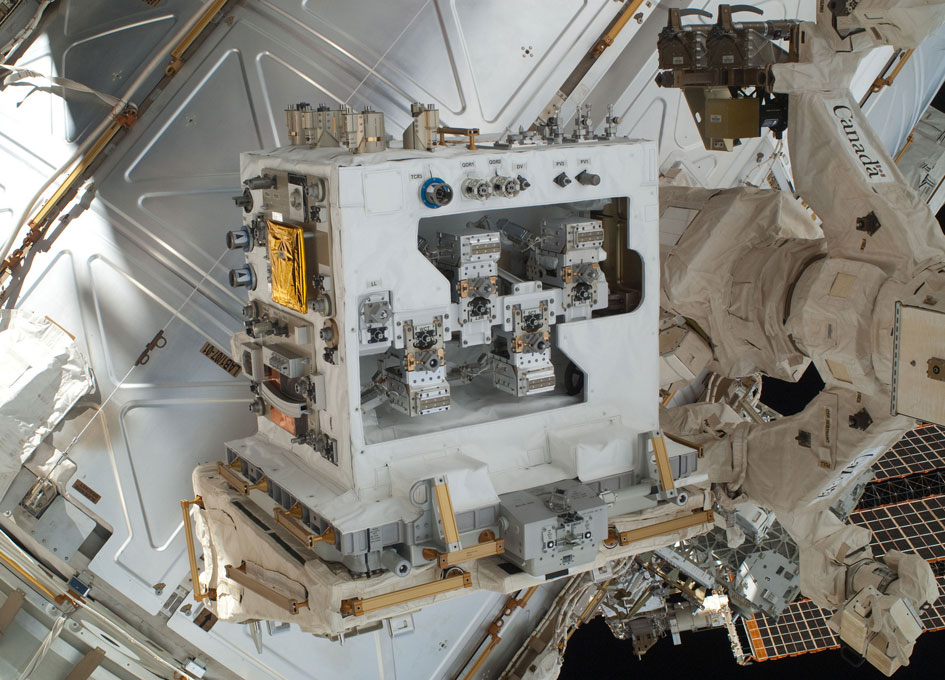

The Japanese HTV cargo vehicle, currently scheduled to launch on Aug. 3, will deliver a new task board and the RRM On-orbit Transfer Cage (ROTC), an original device designed to transfer hardware outside of the space station. Astronauts will mount the ROTC on the sliding table within the Japanese airlock and then install the task board onto the ROTC, giving the Canadian Dextre robot an easy platform from which to retrieve and subsequently install the new hardware.

A second shipment in 2014 will bring a second task board and a new device called the Visual Inspection Poseable Invertebrate Robot (VIPIR). This SSCO-built borescope inspection tool provides a set of eyes for internal satellite repair jobs. Both also will be transferred and installed on RRM via the Japanese airlock, ROTC and Dextre.

With the help of the twin-armed Dextre robot, the newly installed RRM task boards, and the RRM tools, the RRM team will then work its way through intermediate steps leading up to cryogen replenishment. After retrofitting valves with new hardware, peering into dark places with the aid of VIPIR and creating a pressure-tight seal, the RRM and Dextre duo will stop short of actual cryogen transfer for this round of tasks.

RRM Phase 2 operations are scheduled to begin in 2014. Initial activities to demonstrate this in-orbit capability – cutting wires and removing caps – were completed in 2012 with the aid of the original RRM tools and activity boards.

Expanding Capabilities and Fleet Flexibility in Space

Cryogenic fluids are used on the ground and in space to make very sensitive cameras work better. However, in time this extremely cold substance leaks out, and the camera no longer performs well. Robotically replenishing these reserves, explains Reed, would allow spacecraft instruments to last past their expiration date and ultimately permit satellites to perform longer.

“It’s all about expanding options for fleet operators, in both the government and the commercial sectors,” Reed said. “Instead of retiring an aging observatory or spacecraft – and perhaps launching a new, costly, one – [operators] could choose to extend their lives by calling on a future cryogen-toting space tow truck. The RRM demonstrations are an important step to eventually enabling this capability.”

Preparing for a Servicing-Enabled Future

“Since its launch to the ISS in 2011 on the last shuttle mission, RRM has been steadily practicing robotic satellite-servicing activities on orbit,” says Jill McGuire, RRM project manager at SSCO. “A joint effort with the Canadian Space Agency, RRM uses the space station as a test bed for technology research and development.”

On July 17, RRM was named a “Top Exploration Technology Application from the International Space Station in 2012” at the second international ISS Research and Development Conference in Denver. McGuire accepted on behalf of the team.

NASA developed RRM to demonstrate how remotely-operated robot mechanics could extend the lives of the hundreds of satellites residing in geosynchronous-Earth orbit (GEO). Costly assets traveling about 22,000 miles above Earth, GEO spacecraft deliver such essential services as weather reports, cell phone communications, television broadcasts, government communications and air traffic management. Servicing capabilities could greatly expand the options for government and commercial fleet operators in the future. They could potentially deliver satellite owners significant savings in spacecraft replacement and launch costs.

NASA continues to test capabilities for a new robotic servicing frontier. In conjunction with RRM, the SSCO team has been studying a conceptual servicing mission while building the necessary technologies, including an autonomous rendezvous and capture system, a propellant transfer system and specialized algorithms to orchestrate and synchronize satellite-servicing operations.