Microgravity Science Glovebox Celebrates 20 Years of Success

Thinking outside the box propels many NASA innovations for missions exploring space and improving life on Earth.

But thinking – or working – inside the box makes scientific discoveries possible aboard the International Space Station.

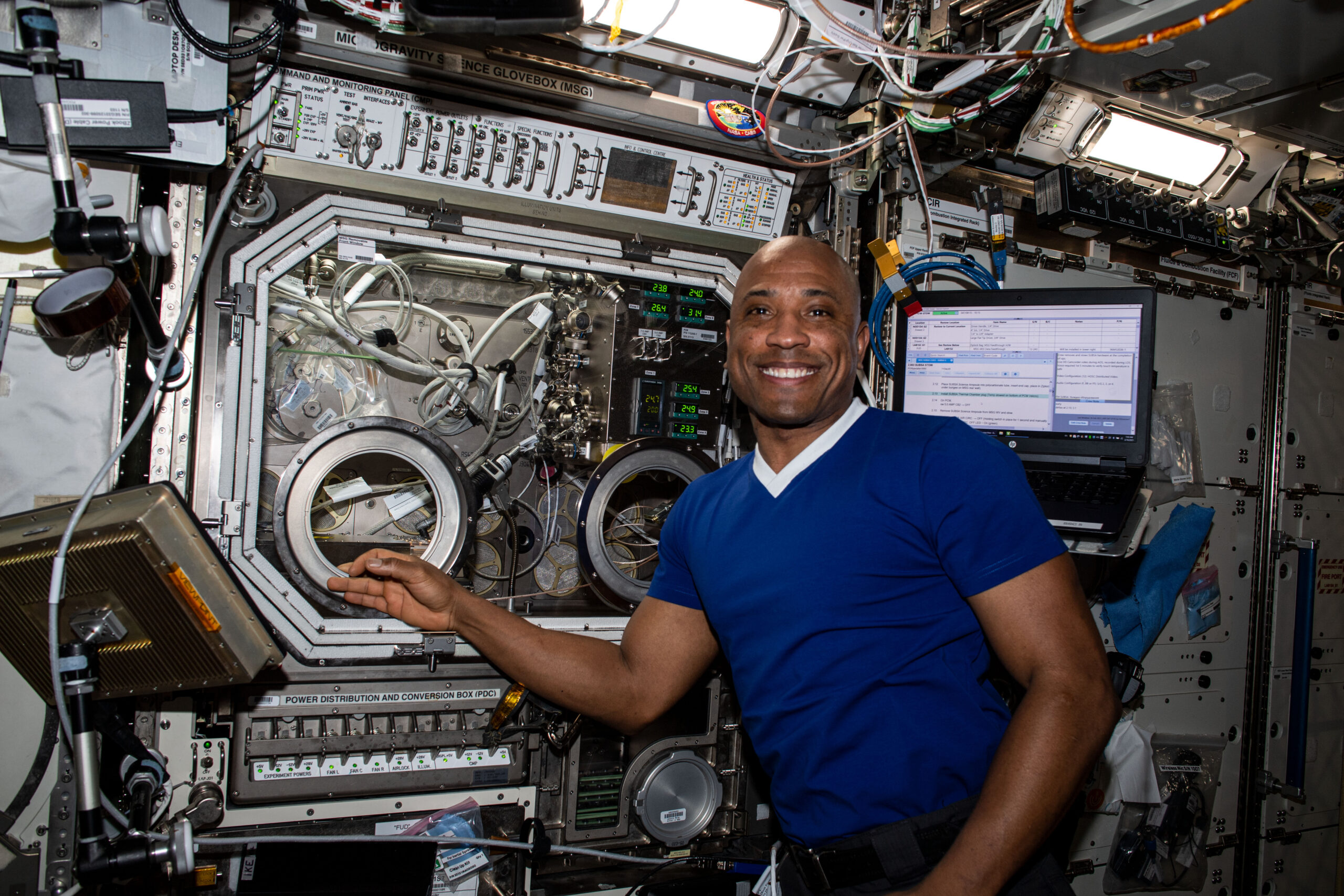

The box is the Microgravity Science Glovebox, or MSG, which celebrated its 20th anniversary aboard the space station July 8. Managed by NASA’s Marshall Space Flight Center in Huntsville, Alabama, the unique lab is designed to closely simulate working conditions on the ground.

Since MSG’s installation, space station crews and scientists around the globe have conducted 63 experiments, many operating multiple times. The glovebox has accumulated 70,000 hours of operational time.

“MSG is like a workhorse, a tank,” said Chris Butler, payload integration manager for the glovebox at Marshall, who has worked with the hardware since before it was launched to the space station in 2002. “We’re 10 years past its expected life expectancy, and it’s been certified through 2030.”

MSG is a sealed facility that provides an enclosed space for investigations conducted in the low-gravity, or microgravity, environment created on the space station. The glovebox offers a safe environment for the crew to conduct research with liquids, flames, and particles used as a part of everyday research on Earth. The glovebox features two levels of containment to protect crew members as they conduct investigations 250 miles above Earth. It contains any leaks, and an air filtration system captures aerosols and other potentially harmful particles.

The European Space Agency, or ESA, developed MSG in a joint venture with NASA. The glovebox is roughly 3 feet wide and 2 feet high, with a 9-cubic-foot workspace where crew members use built-in glove ports to safely manipulate research elements. Its integrated power, data acquisition, and communications systems permit researchers to pursue small and midsized investigations in the areas of fluid physics, combustion science, biotechnology, materials science, and more. Crews are trained to operate MSG at NASA’s Johnson Space Center in Houston. The Marshall team oversees all payloads from its Payload Operations Integration Center.

The protection of MSG allows scientists to explore the effects of microgravity in the fields of physical and biological science, making it central hardware for hands-on research. Crews can view their work from a large acrylic window and a camera inside the glovebox makes it possible for scientists on Earth to watch experiments as they are performed.

Space station partners have also commissioned a second dedicated facility, the Life Sciences Glovebox, to ease demand. Marshall also manages the Life Sciences Glovebox, which was built specifically for biological research and installed on the space station in 2018.

The MSG Project Office at Marshall was responsible for technical oversight of ESA’s development effort. NASA handed over management of MSG to the Marshall team after its delivery to the space station. A glovebox at Marshall permits the testing of materials and the evaluation of safety threats before crews conduct experiments in microgravity.

Phillip Bryant, lead test systems engineer for the Marshall team, has worked with the MSG from the development stages, having spent several months in Europe during design and testing. He serves as an around-the-clock resource to answer questions for issues that might arise with the glovebox. Bryant says the 20-year anniversary is more than just a number for him. “I worked with the gloveboxes all the way through development and verifications, and I support all the safety reviews and any issues in orbit,” Bryant said. “These are my babies.”

Future experiments with MSG include studies in fiberoptics, combustion, fluid flow, and semiconductor growth. Scientific investigations on the space station are also crucial as NASA prepares to return human explorers to the Moon and journey on to Mars.

The Human Exploration Development and Operations Office at Marshall held a celebration July 8, commemorating the 20th anniversary of MSG. The anniversary comes less than a month after NASA recognized another extraordinary milestone of a project Marshall manages. EXPRESS Racks – properly known as “EXpedite the PRocessing of Experiments to the Space Station” multipurpose payload shelving units – reached 1 million hours of cumulative service on the space station June 14. The racks were developed, built, and tested at Marshall.

Ginger Flores, director of Marshall’s Human Exploration Development and Operations Office at Marshall, said the center’s involvement with MSG enables research from scientists that might not have been possible otherwise.

“The project team at Marshall has been responsible for integrating all of the experiments into MSG since 2002,” Flores said, who is also a former MSG project manager. “This is important science for future space exploration and to make life better on Earth. Its success story is a direct result of the decades of dedication of this team.”

More information about the Microgravity Science Glovebox is available online.

For more information about the International Space Station, visit: https://www.nasa.gov/mission_pages/station/main/index.html